HEAT EXCHANGERS

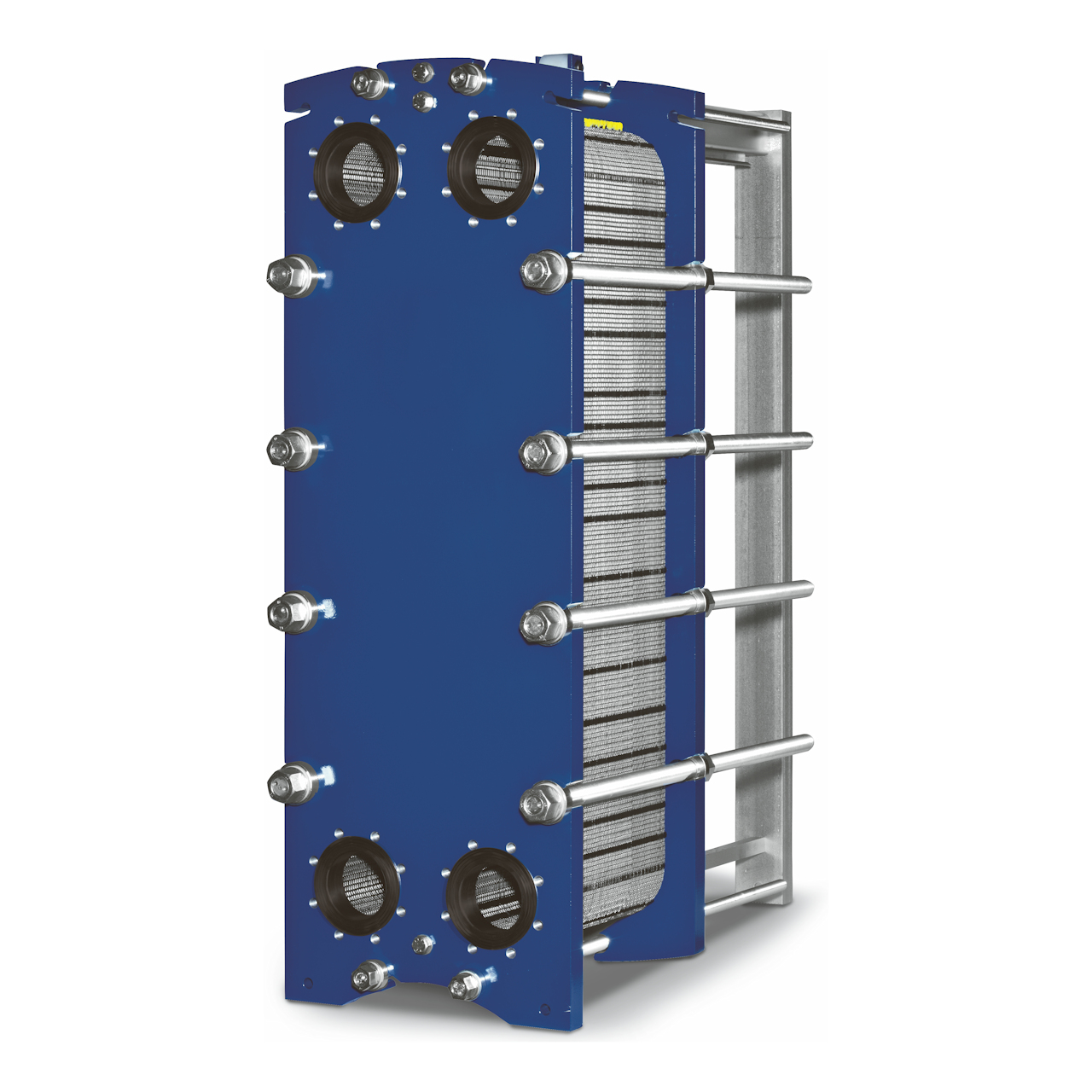

Plate Heat Exchanger

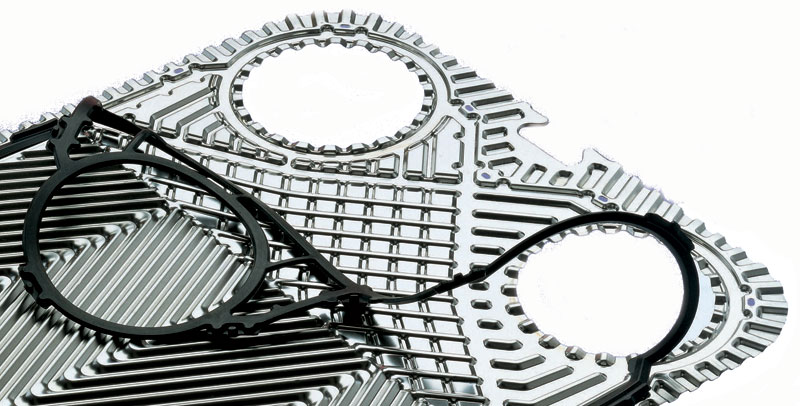

A plate heat exchanger is a compact type of heat exchanger that uses a series of thin plates to transfer heat between two fluids.

There are four main types of PHE: gasketed, brazed, welded, and semi-welded.

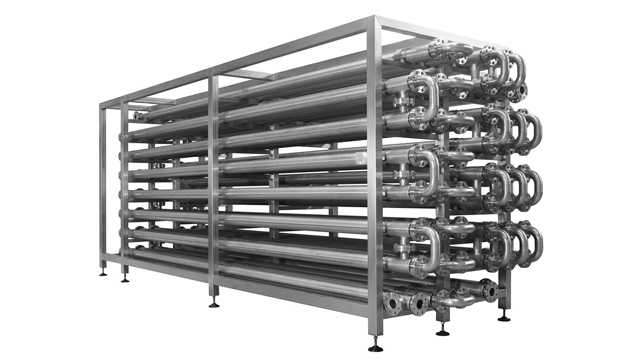

Tubular Heat Exchanger

Tubular heat exchangers, instead of transferring heat through parallel plates, shell and tube heat exchangers transfer heat between a bundle of tubes surrounded by a large shell vessel. Fluids that run through the tubes exchange heat with fluids that run over the tubes contained by the shell.

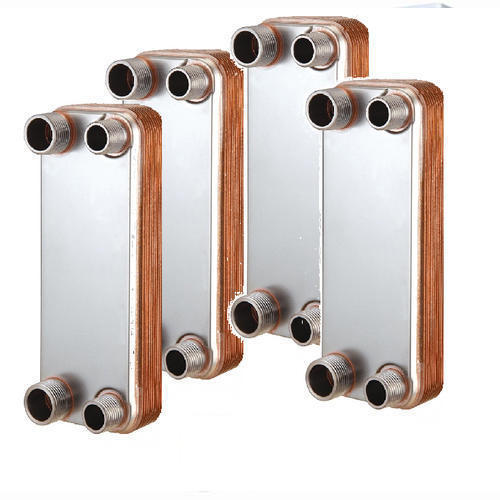

Brazed Plate Heat Exchangers

The brazed plate heat exchanger (BHE) consists of thin corrugated stainless steel plates vacuum brazed together using copper as the brazing material. Design Brazing the stainless steel plates together eliminates the need for sealing gaskets and thick frame plates.

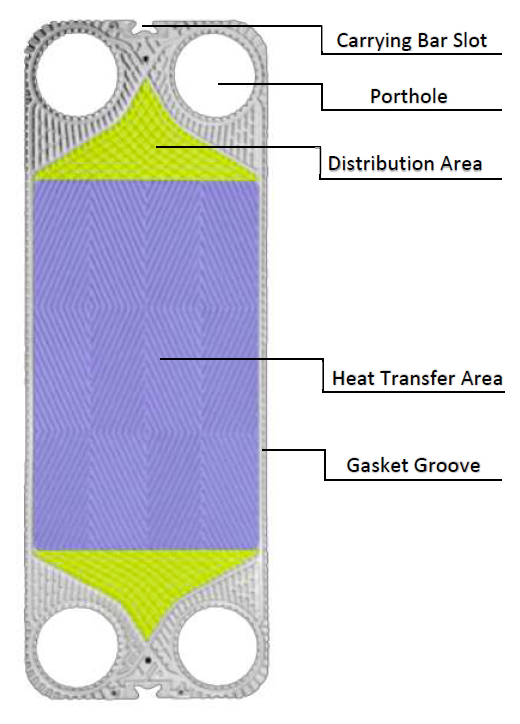

PLATE HEAT EXCHANGER

There are a lot of different specifications when choosing the correct plate for different functions:

Plate Material Selection:

- SS304 & SS316 (Most commonly used)

- Titanium (Used in corrosive environment of seawater)

- Hastelloy/C-276 (Widely used in organic acid)

- Nickel (Commonly used in concentrate caustic solution)

Patterns:

Different kinds of pattern are designed to support various of fluid or gas under levels of pressure rate.

For the purpose of increasing the heat transfer area, and make turbulence more frequent, which greatly improve the heat exchanger efficiency.

Thickness:

- Thinner plates promote better heat transfer

- Thicker plates are able to withstand higher pressure

GASKETS

There are a few different specifications when choosing the correct gasket for different application:

Material Selection:

- EPDM (Ethylene Propylene Diene Monomer)

- NBR (Nitrile Rubber)

- FPM/Viton(Fluro Rubber)

- CR (Chloroprene Rubber)

Temperature requirement:

Due to different processing needs, different gasket materials will have different heat resistance.

Product/Media:

Selection of gasket materials will also greatly depends on the media/product that it will be in contact with.